Installation Technique: The Key to Longevity and Success

Artificial Lawn - Site Base Preparation

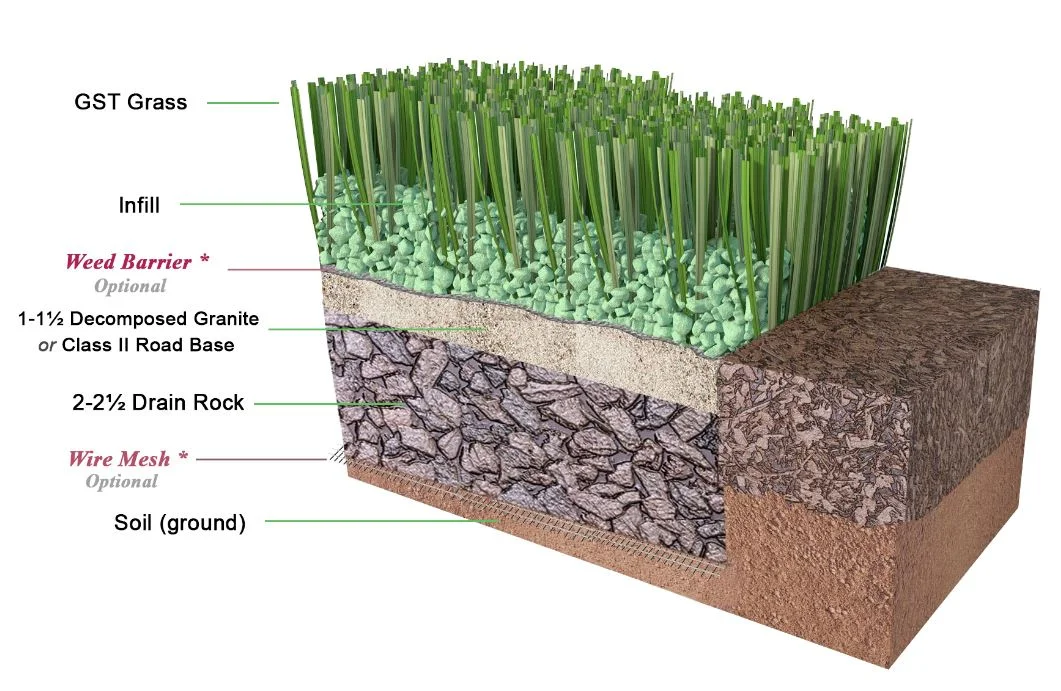

1. Remove 3 - 4 inches of existing sod and/or dirt. Cap and/or remove any sprinklers. Be sure to set a rough grade for drainage.

2. Lay 2 - 2 ½ inches of drain rock, hose down, then using a vibrating plate compactor, compact to 90%.

3. Lay 1 – 1 ½ inches of either class II road base or decomposed granite.

4. Lay the weed barrier * fabric over road base or decomposed granite. This step is optional. Landscape fabrics have their pros and cons. If the soil beneath your installation is “alive” and weeds are wildly grown prior to installation, it might be a good idea to protect your lawn from weeds with weed barrier fabric. In many case scenarios, there is no big need in weed protection, and you can install turf right on top of decomposed granite without adding extra layers.

5. Hose down and then use a vibrating plate compactor to compact to 90%.

6. Make sure base surface is as level and as smooth as possible.

7. Create a slight grade for optimal drainage.

Synthetic Turf Installation

CAUTION: Turf should be rolled out under the sun with blades facing down at least 1-2 hours before installation. This will allow the turf to acclimate and as a result make it easier to work with.

8. Lay out turf onto base and position where needed. Using a carpet knife/razor knife, cut off excess turf on the backside (3 stitches in from sides). Cut turf (on backside) to fit area.

9. Fasten one end with 40D or 60D Bright Common nails or of 5-6 inches in length, spaced 3-4 inches apart along the edges. Stretch turf and fasten with nails as you move across to the opposite end. Place a nail every 12-24 inches throughout center and every 3-4 inches along the perimeter.

10. EasySeam machine and seaming tape should be used to secure seams. Apply tape lengthwise to the bottom side of turf, lining up the turf edges with the orange lines on the seaming tape. Use EasySeam machine to activate the glue on the seaming tape. Fasten together seams by using 11 gauge 6”x1”x6” staples spaced 4 inches apart along the seam. Do not counter sink staples.

Note: Be sure the seams are taut and precise, the grain of the turf is all facing in the same direction, and the space at the seam is the same as the stitching gauge.

11. After turf is installed, power broom before applying infill. Apply infill onto turf using a drop spreader.Spread infill as evenly as possible with a grading rake or broom until infill settles into the base of the turf.Note: Never use regular sand for infill.

12. Hand or power broom again so that the blades are standing straight up. Use carpet scissors to trim off the excessive turf blades. Clean the surrounding area with a blower or a broom.

When to Install a Wire Mesh?

As you can see on the diagram above, a wire mesh installs on the top of a soil, after you removed dirt and existing sod, and before you start spreading and compacting drain rocks and decomposed granite. A Wire Mesh, or a wire barrier is meant to prevent gophers and moles from damaging lawns. Are those critters populated in your area? Then, no matter what type of lawn you install, natural or artificial, you want to protect it. There are special "gopher wires" that made specifically for this reason – to make strong underground barrier below the surface of your lawn. But again, this step is optional. Some regions have no issues with gophers, while in others gophers’ over-population affects the whole gardening and landscaping experience. Gophers love to tunnel their way up your lawn, and to turn it into their personal salad bar. They are not too interested in artificial turf with rocks and granite underneath it. If there are no problems with gophers and moles in your installation area, a wire mesh can be an unreasonable expense.

Tips for a Professional-Looking Synthetic Grass and Turf Install

Prior to installation lay turf out under the sun for at least 1-2 hours to allow turf to acclimate. This will make the backing less stiff and the turf easier to be broomed up. Always stretch and install turf taut. One yard of base materials will cover 80 square feet at 4 inches depth (1 Yard = 1 Ton). Do not overlap seams. Never drive nails into base too far because this will create a noticeable dip.

Always hand or power broom turf prior to filling.

Always run grain of turf in the same direction. Use a 2x4 (straight line installation) or 1x2 (curve line installation) of synthetic or pressure treated wood bender board around the perimeter of turf area to frame and protect the turf from soil and debris.

Use only manufacturer recommended infill materials. Infill amount will vary. A 100 Ib. bag of infill will typically cover a 60 sf. of turf.

Artificial Grass Installation - Facts You Need to Know

Melting: Beware of highly reflective windows on the south or west side of your home. In certain conditions, sunlight hitting these windows has created a "magnifying glass effect", that acts much like a laser and will melt your turf. A coating on the outside of the window will prevent this.

Weather: Our turf gets installed in the mountains, where rain and snow drain very well with no flooding issues. Wind is not a worry if the installation has been done properly. In the hot Southwest part of the US, the grass can get quite warm to the touch during the midday direct sun. The grass does not retain heat in the shade or darkness like rock does. The turf can easily take even the hottest direct sunlight without damage providing that there isn't any strong reflection or sun magnification.

Pets Smell: The best solution for getting rid of pet’s smell is to use ZeoFill. It works as a molecular sieve creating a cation exchange which occurs when two or more positively charged compounds or elements exchange places on a negatively charged host. This exchange process removes charges and essentially removes ammonia in pet waste.